Editor’s Note: Fragmented processes and changing internal customer needs always keep the procurement leaders on their toes to stay on top of supply chain market innovations. Category management is no exception. Know how to take your procurement capabilities to the next level.

Previously on category management, we’ve spoken about where to start, what the principles are, and a practical 8-step guide to it. Here, we take it to the next level by talking about what the KPIs are and how to ensure effective category management with a few best practices. Till now we’ve seen what category management is, before we go into further details let’s take a trip to see what it is not. This understanding will reinforce the importance of how to proceed with the category analysis.

What Category Management is not?

Category Management is not strategic sourcing

Strategic sourcing is a part of category management. Strategic sourcing is short-term and is limited to a single or few categories. It is more like a one-time consideration to ensure low cost for fulfilling immediate needs. Instead, category management also involves supplier management and building relationships for a long-term perspective.

Category Management is not Supplier relationship management

Supplier management is part of the broader category management just like strategic sourcing. It is also such a component that makes managing categories beneficial in the long-run. Right from supplier selection and evaluation to assessing their risk, supplier management plays an important role in category management.

Category Management is not a one-time implementation

The goal of category management is to maximize value, reduce costs, and enhance supplier relationships through a holistic approach to procurement. This is well known. But most leaders approach this like a one-time approach. Let’s go back to our organizing analogy – it’s not over once you organize this – you have to keep maintaining and revisiting it in case any changes are needed.

Next, let’s try and understand how to measure the success of your strategies, supplier relationships, and overall procurement activities within different spend categories i.e., the KPIs.

KPIs for effective category management

There are multiple KPIs that can be measured for a better understanding of category management. Some of them include Category Turnover, Gross Margin, Cost avoidance, Spending under management, Category compliance, Supplier Diversity, Profit by category, etc.

But instead of viewing category management separately let’s take a step forward and view it as a part of procurement and then discuss the KPIs.

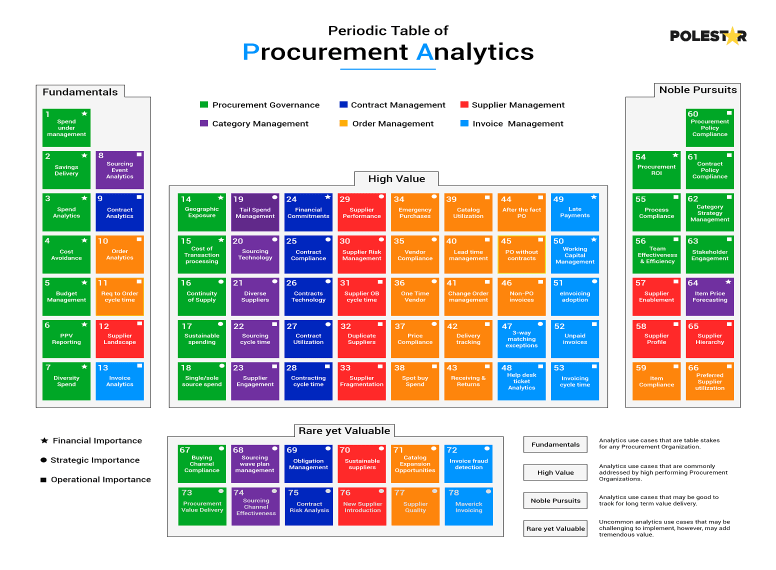

Here are the most important KPIs for Procurement Governance, Contract Management, Supplier Management, Category Management, Order Management, and Invoice Management.

Please note: The periodic table of procurement analytics is the copyright of Polestar Solutions and cannot be repurposed without proper accreditation.

Understand the Procurement Analytics framework, including the procurement maturity model for better analytics adoption.

Let’s now take a look at the ones relevant for category management:

Certainly, these are excellent KPIs that can be used to measure different aspects of category management. Let's take a closer look at each KPI:

1. Sourcing Event Analytics: This involves measuring the success of different sourcing events, such as RFPs (Request for Proposals) or reverse auctions. This can help evaluate the effectiveness of your sourcing strategies to identify cost savings, supplier participation, and time saved.

2. Tail Spend Management: Tracking the reduction of lower-value, often unmanaged purchases as a percentage of total spending indicates efficient category management efforts.

3. Supplier Diversity: A well-rounded supplier base that aligns with your organization's diversity and inclusion goals. This can ensure providing a wide range of companies with free and fair opportunities to bid for, and win, work.

4. Sourcing Cycle Time: Measuring the time it takes to complete a sourcing event (from identification to contract finalization) helps assess procurement efficiency and the speed of category management activities.

5. Supplier Engagement: Monitoring the level of engagement and collaboration with suppliers can provide insights into the strength of your supplier relationships and the success of your category management efforts.

6. Item Price Forecasting: This predicts future prices of items within a category. Accurate forecasting enables proactive decision-making and better negotiation strategies.

7. Sourcing Wave Plan Management: Sourcing wave planning involves scheduling procurement activities strategically. Monitoring how well-planned waves are executed helps optimize procurement timing and resource allocation.

8. Sourcing Channel Effectiveness: Evaluating the effectiveness of different sourcing channels (e.g., online platforms, direct negotiations) helps identify the most efficient and successful methods for different categories.

Though each of these KPIs is broader and might have more sub-parameters, these will help organizations measure and evaluate efforts effectively by taking the procurement function as a whole.

Category management challenges and your expert guide to effective mitigation

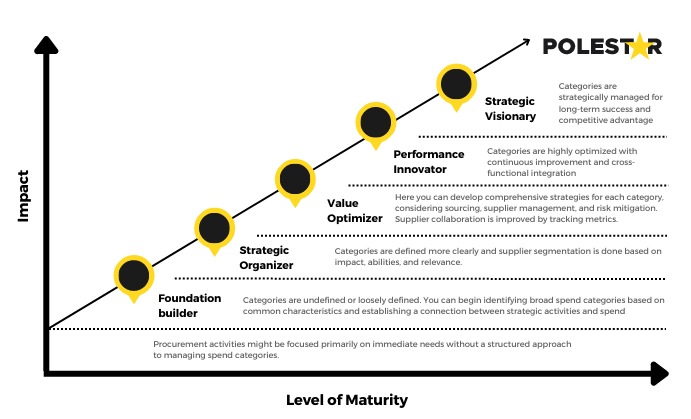

Do you think a startup would have the same challenges as an MNC? Probably not. Similarly, though most organizations face some common challenges the more specific ones would depend on where the organizational capabilities and maturity stand.

It is the same with category management too. The challenges faced would depend on the level of maturity (refer to the image below) and their overall strategy and adoption.

A few challenges that can be faced by companies in these varying maturities are:

Level 1: Foundation Builder: They lack clarity in category definitions and objectives and have a limited understanding of the business goals and procurement practices.

Level 2: Strategic Organizer: They have difficulty prioritizing categories based on their strategic importance and have difficulty evaluating and segmenting suppliers

Level 3: Value Optimizer: They face challenges in balancing short-term cost savings with long-term supplier relationships

Level 4: Performance Innovator: They find it difficult to integrate category management with cross-functional teams and departments

Level 5: Strategic Visionary: Though this might sound like a place where all the companies need to reach they also face issues in maintaining a forward-looking approach amidst organizational complexities

Common challenges faced by organizations across all maturity levels

In addition to the above-mentioned challenges, the following challenges can be seen at varying degrees in organizations.

Manage your contracts, invoices, suppliers, spending, and orders in addition to categories.

Procurement category management best practices

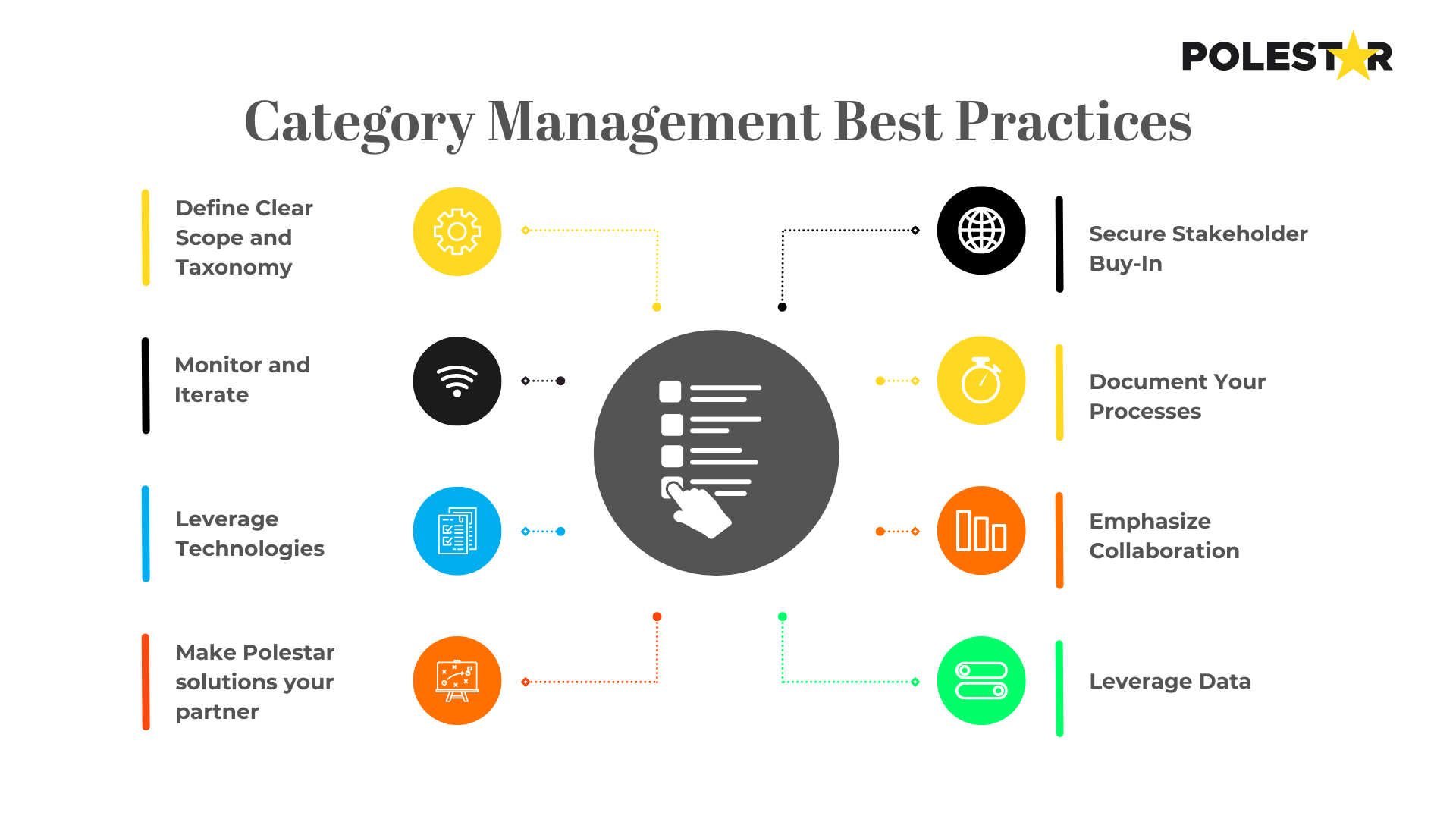

Now that we have understood the process and the challenges behind category management, let’s take a look at few of the best practices that every procurement leader should take care of:

Secure Stakeholder Buy-In: Gain support from key stakeholders by showcasing the strategic benefits of category management. Highlight cost savings, risk reduction, and improved supplier relationships to ensure organizational alignment.

Document Your Processes: Establish detailed and standardized category management processes. Document workflows, roles, responsibilities, and decision-making criteria to ensure consistency and transparency across the procurement lifecycle.

Emphasize Collaboration: Foster cross-functional collaboration by involving departments beyond procurement. Engage finance, operations, and marketing to align category strategies with overall business goals and requirements.

Leverage Data: Utilize advanced analytics and business intelligence tools to derive actionable insights from spend data. Identify trends, opportunities, and potential risks to make informed decisions and drive continuous improvement.

Define Clear Scope and Taxonomy: Define precise category scopes and establish a well-structured taxonomy. Categorize spend items with precision, enabling accurate analysis, reporting, and strategic decision-making.

Monitor and Iterate: Continuously monitor category performance against established KPIs. Regularly review category strategies, adapting to changing market conditions and organizational needs for ongoing optimization.

Leverage Technologies: Implement cutting-edge procurement technologies. Utilize AI, machine learning, and automation to enhance data accuracy, supplier collaboration, and real-time decision support.

The way forward: leveraging the data

In this ever-evolving landscape leveraging the data can unlock new avenues for cost savings and efficiency. But to do it efficiently you need to have proper data quality and decentralization, strategic alignment, advanced analytics capabilities, etc., that’s where we can help you! Reach out to us to optimize your data lifecycle.